Cerdanyola del Vallès, 3rd June 2019 The development of the polymers science and technology has facilitated our lives and has been one of the engines of today's society. From the clothes to industrial infrastructures, polymers are part of many materials used every day. The great versatility of polymers is largely characterized by its internal structure: the monomers that contain, its molecular weight and its degree of crosslinking. Synchrotron light techniques allow the detailed characterization at the molecular level of their structure, to predict if a certain product will have the desired behaviour or even for the design of more durable materials or with certain properties. Without any doubt, the 21st century faces new challenges in terms of improving the properties of polymers as well as their recycling and biodegradability capabilities, where the advanced technologies of the ALBA Synchrotron can also be of great help.

The workshop was held in collaboration with Federació Empresarial Catalana del Sector Químic (FedeQuim) and the European project CALIPSOplus. The director of the ALBA Synchrotron, Caterina Biscari, its Scientific Director, Klaus Attenkofer, and the Director of FedeQuim, Joan José Meca Saavedra, welcomed the attendants encouraging them to take profit of the synchrotron techniques available at the ALBA Synchrotron. Next, Miguel Ángel García Aranda, former ALBA Scientific Director, explained the functioning of the Synchrotron and its techniques. Later, Núria Valls, Industrial and Projects office scientist, commented how companies can interact with ALBA to obtain services related to materials characterization.

Different presentations by scientists of ALBA showed to the attendees the different application of its cutting-edge techniques for obtaining valuable information at the nanoscopic level of many different polymeric materials, such us plastics, adhesives, 3D printing and biomedical materials. Among them, infrared microspectroscopy that enables to characterise materials as well as to heat and/or stretch them to analyse the modifications and its molecules orientation; X-rays absorption spectroscopy and X-rays diffraction, which gives structural information of the polymers and shows its fibres orientation, useful for improving mechanical properties of the materials.

In addition, the event showcased specific studies carried out in ALBA by the companies B. Braun Surgical, Samtack and Henkel as well as the research group PSEP- Synthetic Polymers, Structure and Properties from the UPC. These techniques can enhance several processes related to polymer industry and thus promote a significant impact on companies' economy and social image.

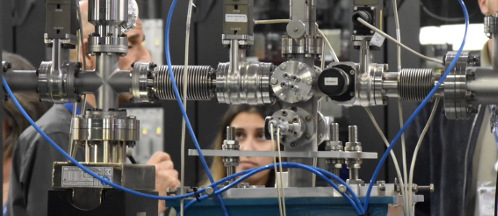

The event finished with a visit to the experimental hall and beamlines and with a networking lunch in tents outside ALBA building where all attendees could have relaxed talks with the scientists and other companies. According to the comments realized by the attendees the workshop was very interesting and they were satisfied with the talks and the visit to the facilities and look forward to benefit from ALBA techniques.

This seminar has been the 7th industrial seminar organized by the ALBA Industrial Liaison Office. Previous editions were devoted to Metallurgy Industry (2018), Pharma and Cosmetics (2017), Agri-food and packaging (2017), Cements, pigments, ceramics and glasses (2016), pharmaceutical sector (2015) and the chemical industry (2014).