Do you want to keep up to date? Subscribe to our newsletter. 1mail every 2months! |

|

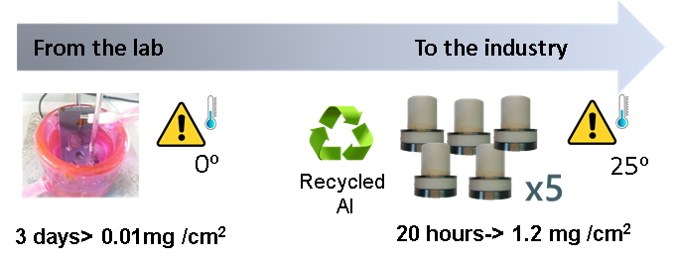

Figure: Protocol developed during the project to increase the number of nanowires for industrial applications.

Cerdanyola del Vallès, 2nd December, 2021. Nanotechnology is one of the major driving forces behind the technological revolution of this century and nanomaterials play a key role in this revolution. While the use of nanoparticles is widespread in industrial applications, the use of nanowires -wires with a diameter of only a few nanometres- is mostly reduced to scientific areas. The fields of biomedicine and permanent magnets would benefit from the cost-effective mass production of nanowires.

In a recent publication, researchers from the Universidad Complutense de Madrid (UCM) and various centres from the Consejo Superior de Investigaciones Científicas (CSIC), in collaboration with ALBA, have established a novel and sustainable synthesis protocol that allows obtaining a greater number of nanowires than conventional laboratory fabrication processes with considerably reduced production time and cost.

The goal of this project was to increase the production of metallic nanowires, reducing costs and timings to expand their applicability to industry. Due to the high costs associated with the high-purity aluminium normally used as the starting material, as well as with the low temperature and large anodization time, the commercial application of nanowires using anodized aluminium oxide is still limited by their fabrication process.

In this research, to reduce costs, recycled aluminium from the waste of mechanical shops was used as initial material and the nanowires growth process was done at room temperature, without the need of temperature stabilization. Despite the aluminium impurities in the recycled foils, very similar magnetic properties were obtained compared to the high-purity aluminium foils.

In addition, as the potential oxidation during storage is one of the main problems of metallic nanowires in applications, researchers explored the use of ethanol to conserve them for several months. Results showed that this component was suitable to storing nanowires without changing their structural and magnetic properties. These discoveries pave the way toward the implementation of metallic nanowires in real world applications such as biomedicine or permanent magnets.

As a proof of concept, a permanent magnet composed of a mixture of ferrite and nanowires produced with this technique was synthesized. Results showed an enhancement of the energy product of 48% compared to pure ferrite magnet. This extremely promising result brings forward nanowire-ferrite composites as a clear candidate for gap magnets that could fill the void between ferrites and rare-earth magnets.

This study is part of the European AMPHIBIAN project, with the collaboration of the Universidad Complutense de Madrid (UCM), the Instituto de Cerámica y Vidrio (ICV-CSIC), the Instituto de Química Física Rocasolano (IQFR-CSIC) and the ALBA Synchrotron.

Synchrotron light techniques

The experiments, carried out at the CIRCE beamline in the ALBA Synchrotron, allowed the magnetic properties of the nanowires to be evaluated. In particular, Photo Emission Electron Microscopy with X-ray Magnetic Circular Dichroism (XMCD-PEEM) measurements revealed the magnetic configuration of the nanowires and their magnetic behaviour, crucial information to implement the nanowires in permanent magnet applications.

In addition, X-ray Absorption Spectra (XAS) of the nanowires after storage in ethanol were performed. Results proved that storage in ethanol ensures the conservation of the synthesized nanowires, preventing them from oxidation and keeping their magnetic properties suitable for application as a component of a magnetic nanocomposites.

Reference: Claudia Fernández-González, Jesús C. Guzmám-Mínguez, Alejandra Guedeja-Marrón, Eduardo García-Martín, Michael Foerster, Miguel Ángel Niño, Lucía Aballe, Adrián Quesada, Lucas Pérez and Sandra Ruiz-Gómez. Scaling Up the Production of Electrodeposited Nanowires: A Roadmap towards Applications. Nanomaterials (2021). DOI: https://doi.org/10.3390/nano11071657

With the collaboration of Fundación Española para la Ciencia y la Tecnología. The ALBA Synchrotron is part of the of the Unidades de Cultura Científica y de la Innovación (UCC+i) of the FECYT and has received support through the FCT-20-15798 project.